What are the tips to follow for the maintenance of the conveyors?

Many different types of enterprises might benefit from conveyors from the top conveyor manufacturer in Saudi Arabia. They are essential for transporting objects from one location to another. How might a conveyor system malfunction, though? It may result in lower output, prolonged downtime, and lower income.

As a result, even if you get the best system from a reputable conveyor supplier, it still needs to be properly maintained in order to function at its peak. We'll go over a few things you should look out for when maintaining the conveyors here.

Frequently Asked Questions about Conveyor Saudi Arebia

A conveyor from a top quality conveyor manufacturer has certain parts. The users must check every part of the machine to keep it running smoothly. Therefore, the users should regularly inspect the belts, bearings, rollers, and motors for the conveyors. You must check for any misalignment or damage in the conveyors. Additionally, the worn-out portions of the conveyors should replaced to prevent breakdowns and ensure smooth working.

Conveyors must be cleaned regularly to remove the dirt and debris off the machine. It also helps in eliminating the spills that could jam the machines. A conveyor supplier will provide you with cleaning instructions when you purchase their conveyors. To keep the conveyors in optimal condition, make sure you clean and maintain them using air blowers, brushes and hoover systems.

Lubricating the conveyors from the best conveyor manufacturer will reduce friction and prevent wear of the parts like the chains and the bearings. Follow the manufacturer guidelines properly for lubricating the machine. Also make sure to use suitable lubricants to keep the machine in proper working condition.

Adjust belt tension to reduce slipping and ensure proper operation. A conveyor manufacturer will recommend using adjustments or tensioning devices to adjust the conveyor belt. Incorrect adjustment of the belts can cause it to wear and reduce the efficiency

Monitor a conveyor system parts closely to check out worn out and damaged parts. Replace the worn out and damaged components using high quality replacements to minimize downtime and prevent equipment failure. You can also try reaching out to the conveyor manufacturer for parts replacement.

Proper tracking and alignment will prevent misalignment that could lead to permanent wear or failure of the machine. You can use the alignment tools or the adjustment tools from a renowned conveyor supplier in Saudi Arabia to perform centering and tracking effectively.

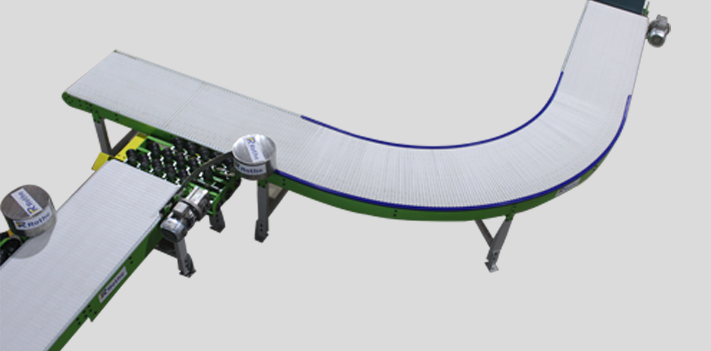

Rothe Packtech is the best conveyor manufacturer in Saudi Arabia who manufacturers the best quality conveyor machines. With their conveyor machines, you can hassle free transport materials from one point to another. Moreover, they are one such conveyor supplier who will always assist you with any issue in the conveyor. Therefore, place your requirements and get a quotation now!