Streamlining Vertical Movement: The Floor-to-Floor Transfer Conveyor System by Rothe Packtech

In the bustling industrial landscape of Pune and across India, efficient vertical material handling solutions are paramount. Rothe Packtech, a beacon of creative innovation, has introduced a game-changer - the Floor-to-Floor Transfer Conveyor System. In this article, we embark on a journey to explore the transformative power of these systems and Rothe Packtech's role in shaping the future.

Floor to Floor Transfer has following applications :

- Logistics

- Warehouses

- Production Lines

- Agriculture Industry

Floor to Floor Transfer has following Features and Benefit :

- Rigid Construction

- Ocupies Less Space

- Wide range product suitability

- Fit & Forget Mechanism

- Increased productivity

Floor to Floor Transfer has following Specifications :

- Operation : Fully automatic

- Product Sorting : Automatic

- Machine Speed : upto 25 Product/min

- Frame Material : SS304/MS

- Motor : Bongfiglioli/SEW/ cycleB/equivalent

- Pneumatic cylinder : Festo/SMC/equivalent

- Compressed air : 4 bar to 6 bar

- Voltage : 220V/380V/415V

- Hertz : 50Hz/60Hz

- VFD : Mitsubishi/AB/Siemens/Delta/equivalent

Frequently Asked Questions about Floor to Floor Transfer

Picture a sophisticated manufacturing facility in Pune, where products glide seamlessly along conveyor belts, undergoing various processes. It's a symphony of efficiency, thanks to Lane Diverters. Rothe Packtech is a manufacturer based in Pune with a nationwide reach. But what exactly is a Lane Diverter, and how does it work its magic on the factory floor?

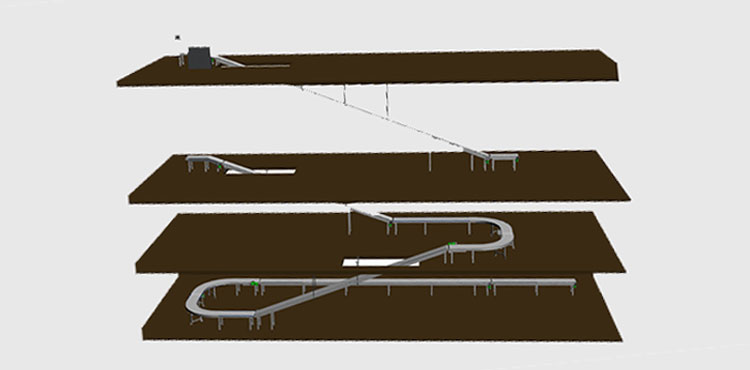

In a manufacturing facility, raw materials and finished products must traverse multiple floors seamlessly. The Floor Floor Transfer Conveyor System is the answer to this challenge. But what exactly is this system, and how is it revolutionizing the manufacturing landscape in Pune and beyond?

At the heart of Rothe Packtech's success lies the art of precision craftsmanship. The Floor Floor Transfer Conveyor Systems they create are a testament to this dedication. But what goes into creating these vertical movement marvels, and how does this benefit industries in Pune and India?

Efficiency is the key to success in a city like Pune, where industries are thriving. The Floor-to-For Transfer Systems offered by Rothe Packtech provide several advantages that directly impact Pune's manufacturing sector. How do these systems optimize material handling and streamline production processes in Pune's industrial landscape?

Automation is a driving force behind the success of Floor to Floor Transfer Systems. These systems have advanced sensors, controls, and precision engineering to ensure seamless vertical material handling. How does automation play a pivotal role in making these systems efficient and reducing the need for manual labor in Pune's factories?

Pune's industrial landscape is diverse, encompassing various sectors with challenges and requirements. Rothe Packtech's Floor Transfer Systems are highly adaptable and can be changed to meet the specific needs of different industries.

In today's competitive market, profitability is a top priority for Pune-based businesses and those across India. Rothe Packtech's Floor Transfer Systems maximize profitability by reducing material handling costs, minimizing downtime, and enhancing productivity.

As Rothe Packtech continues to lead the charge in creative innovation, one thing remains constant - its commitment to excellence. With ongoing innovations and a collaborative approach, they ensure that their Floor Floor Transfer Systems evolve to meet the ever-changing requirements of businesses in Pune and beyond.