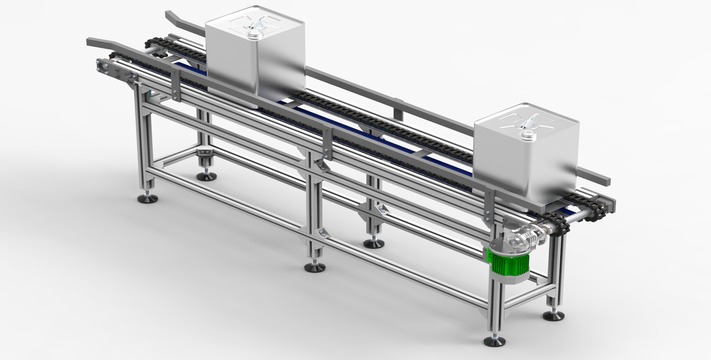

Tin Conveyor: Revolutionizing Material Handling with Rothe Packtech's Expertise

In the world of material handling, precision and efficiency are paramount. Tin conveyors have emerged as a game-changing solution to streamline the transportation of tin and other materials. Rothe Packtech, a renowned manufacturer of conveyor systems, is at the forefront of this innovation, redefining how tin is handled in Pune and beyond. But what makes tin conveyors from Rothe Packtech stand out, and how are they transforming the material handling landscape? Let's explore this journey of innovation together.

Tin conveyor has following applicaions :

- Oil Industry

- Paint Industry

Tin conveyor has following Features and Benefit :

- Tin Conveying

Tin conveyor has following Specifications :

- Conveyor Type : Tin Conveyor

- Frame Material : SS304/MS

- Conveyor Width : 240mm

- Conveyor Length : Customized

- Belt Length : Customized

- Conveyor Profile : Straight

- Height : As per Requirement

- Speed : upto 45m/min

- Motor : Bongfiglioli/SEW/ABB/equivalent

- Motor Position : Right/Left

- Voltage : 220V/380V/415V

- Hertz : 50Hz/60Hz

- VFD : Mitsubishi/AB/Siemens/Delta/equivalent

- Direction : One

Frequently Asked Questions about Tin conveyor

Rothe Packtech thrives on innovation. Their tin conveyors exemplify this spirit, offering state-of-the-art solutions meticulously designed and tested for excellence. Material handling requirements vary widely across industries. Rothe Packtech understands this and provides customized tin conveyor solutions that cater to the unique needs of different applications.

Trust and confidentiality are paramount to Rothe Packtech. They build enduring relationships by addressing challenges discreetly and working collaboratively for mutual success.

Tin conveyors are engineered to redefine efficiency in material handling. These conveyors offer precise control over tin transportation, minimizing errors and optimizing overall efficiency. Whether you're loading, unloading, or transferring tin, these conveyors are the linchpin of streamlined material handling processes.

The diversity of material handling operations demands flexibility. Rothe Packtech understands this and offers highly customizable tin conveyor systems. Whether you're handling tin sheets, cans, or delicate components, these conveyors can be tailored to integrate seamlessly into your specific material handling operations.

Safety is paramount in material handling operations, and Rothe Packtech prioritizes it. Their tin conveyors have advanced safety features, including emergency stop mechanisms, real-time monitoring sensors, and robust protective guards. These measures create a secure working environment, allowing operators to focus on productivity without safety concerns.

As industries in India and beyond continue to evolve, the demand for reliable material handling solutions, including tin conveyors, is rising. Rothe Packtech's unwavering commitment to innovation ensures that these conveyors remain at the forefront of material handling advancements.

Tin conveyors are a beacon of innovation in material handling, where precision, adaptability, and efficiency are non-negotiable. They represent the next chapter in the ongoing story of material handling, where adaptability and innovation work harmoniously to propel industries toward greater productivity and success.

Tin conveyors from Rothe Packtech aren't just machines; they are architects of a new era in material handling. Rothe Packtech's expertise in manufacturing these cutting-edge systems positions them as pioneers in Pune, India, and global leaders in the material handling industry. With their unwavering focus on excellence, customization, safety, and innovation, Rothe Packtech's tin conveyor solutions are redefining the essence of material handling, maximizing efficiency and profitability for their valued customers.