Gravity Spiral Conveyor: Enhancing Material Handling Efficiency in India

Gravity spiral conveyors have transformed material handling by efficiently using gravity as a driving force. As industries in India seek optimized solutions for logistical challenges, the expertise of Gravity Spiral Conveyor Manufacturers like Rothe Packetch becomes crucial. So, let us see the pivotal role of these conveyors in driving efficiency and productivity.

Frequently Asked Questions about Gravity Spiral Conveyor

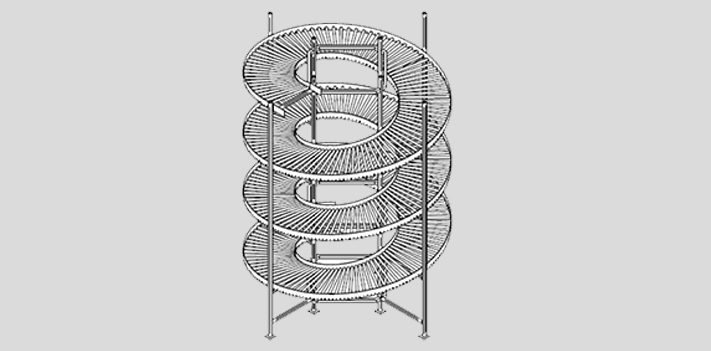

A gravity spiral conveyor is an innovative material handling solution that utilizes the principles of gravity and centrifugal force to transport products vertically or horizontally. This unique conveyor system consists of a spiral-shaped track gently guiding materials along its curvature, allowing for efficient and controlled movement between different levels or locations within a facility.

Implementing gravity spiral conveyors can significantly benefit businesses across various industries in India. These systems offer numerous advantages, including space-saving designs, reduced energy consumption, and considerably improved material flow.

By leveraging gravity as the primary driving force, gravity spiral conveyors minimize the need for powered mechanisms, resulting in lower operating costs and reduced maintenance requirements.

Gravity spiral conveyors are designed with several key features contributing to their efficiency and versatility. These features include:

- Customizable Configurations: Gravity spiral conveyors can be customized to fit a facility's specific layout and requirements, ensuring optimal integration into existing operations.

- Seamless Product Handling: The smooth, curved track minimizes product damage, making these conveyors suitable for handling delicate or fragile materials.

- Modular Construction: Gravity spiral conveyors' modular design allows for easy installation, reconfiguration, and future expansion as business needs evolve.

Integrating gravity spiral conveyors into India's industrial landscape can bring numerous benefits. These systems can help businesses:

- Optimize Floor Space: By utilizing vertical space, gravity spiral conveyors free up valuable floor area, allowing for more efficient use of facilities.

- Enhance Worker Safety: Gravity spiral conveyors minimize the risk of workplace hazards associated with lifting and carrying heavy loads by reducing manual handling.

- Improve Operational Efficiency: Gravity spiral conveyors enable the smooth and controlled movement of materials, streamlining production processes and reducing bottlenecks, leading to increased overall efficiency.

- Reduce Environmental Impact: Gravity spiral conveyors reduce energy consumption and even the carbon footprint by minimizing the need for powered mechanisms, making them sustainable for businesses.

As a leading manufacturer of Conveyors and conveyor Systems in India, Rothe Packtech has extensive expertise in developing innovative material handling solutions, including gravity spiral conveyors.

The company's commitment to excellence and customer-centric approach enables it to design and manufacture gravity spiral conveyors that meet the unique requirements of Indian businesses. Rothe Packtech's gravity spiral conveyors are renowned for their durability, reliability, and efficiency, making them the first choice for businesses seeking to optimize their material handling processes.