How can manufacturers maintain the quality of case erectors?

Automated devices called case erectors are used in packaging lines to build cardboard cases or boxes out of blanks or flat sheets. Because case erector quality directly impacts the packaging process's dependability and efficiency, it is extremely important for any Case Erector Manufacturer.

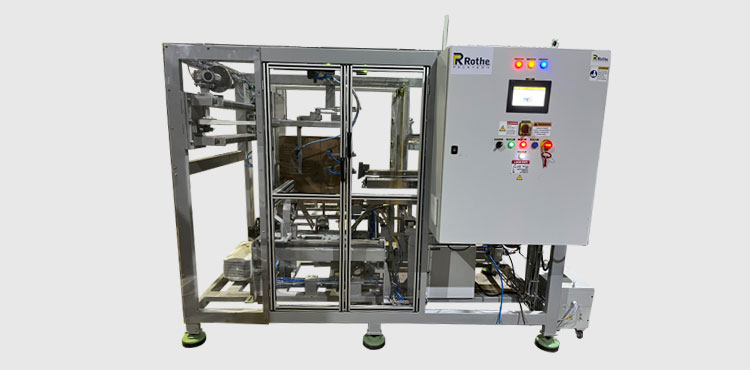

Product damage is minimized, downtime is decreased, box creation is consistent, and overall productivity is increased using high-quality case erectors. Inadequate quality may result in misaligned boxes, more frequent malfunctions, and higher running expenses. Good quality Case Eractor Manufacturers like Rothe Packtech will always ensure that quality is optimal for all its products.

Frequently Asked Questions about Case Erector Russia

Careful quality control is necessary for every Case Eractor Manufacturer and the following essential case erector components:

Some crucial routine maintenance procedures that every Case Eractor Manufacturer follows are:

In any case, Eractor Manufacturer can guarantee component dependability.

By using high-quality components and doing consistent, routine maintenance, every Case Eractor Supplier can preserve the quality of their case erectors. Daily inspections, planned service, meticulous cleaning, software upgrades, and routine calibration are examples of essential maintenance procedures.

The machines are guaranteed to run well and last longer by following these procedures. Furthermore, acquiring parts from reliable vendors, carrying out thorough testing, and abiding by industry standards ensure the machine's component reliability.

A good Case Eractor Supplier in Russia can improve overall performance and reduce breakdowns by employing high-quality parts and executing a systematic maintenance regimen.

Reach out to us to get your hands on the best quality and highly durable case erectors from the most experienced Case Erector Supplier in Russia. All our products are available at the best prices and are highly proficient. Visit our website to learn more about case erectors and our other products.