What is the manufacturing process and aspects related to case Packers?

Automated devices called case Packers are made to assemble cardboard boxes from flat-packed blanks. They are essential to the Case Packer Supplier since they greatly expedite the box assembly process, guaranteeing uniform quality and cutting labor expenses. Businesses can increase their production and efficiency by automating the case erection process. This is especially crucial for high-volume packing operations.

Frequently Asked Questions about Case Packer Canada

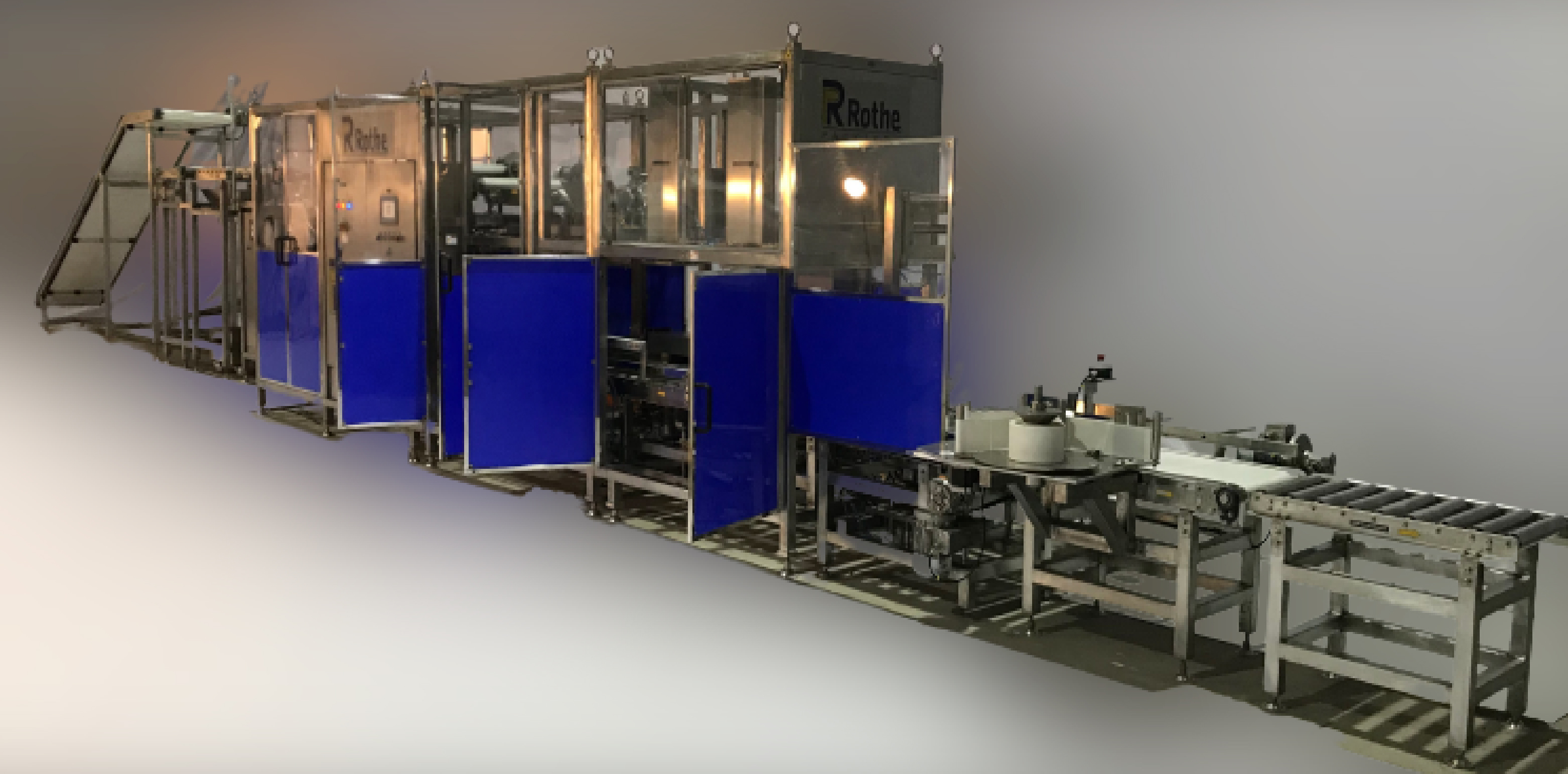

The Case Packer Supplier fabricates the machine's frame, and then the mechanical and electrical components are installed to complete the assembly process. At Rothe Packtech, experts carefully put each component together, guaranteeing accuracy and quality every time. After assembly, the case Packers undergo a thorough testing process to confirm that they operate as intended and live up to the Case Packer manufacturer's high requirements.

Rothe Packtech, the finest Case Packer Manufacturer in Canada, provides comprehensive support and services, including installation, training, and maintenance. They offer customized solutions to meet client requirements and ensure seamless integration with existing packaging lines. Their commitment to customer satisfaction involves providing prompt technical support and spare parts to reduce downtime and maintain operational efficiency.

Every Case Packer Manufacturer maintains their competitiveness by consistently developing and enhancing their goods. They also put a lot of effort into developing long-lasting relationships with their customers by providing dependable and effective machinery along with top-notch customer support. A Case Packer Supplier is able to sustain a competitive advantage in the worldwide market thanks to their reputation for quality and innovation.

To ensure lifespan and durability, the best Case Packer Manufacturer in Canada, like Rothe Packtech, employs premium materials for the frame, like aluminum and stainless steel. They also incorporate advanced electronic components, including programmable logic controllers (PLCs) and sensors, to automate the case erection process. To ensure dependability and performance, these parts are purchased from reliable vendors.

A Case Packer Supplier must enforce strict quality assurance protocols involving several testing stages throughout the manufacturing process. They also follow international certifications and regulations to ensure the dependability and security of their machines. They keep at the forefront of the business by incorporating customer feedback into their products and using it to develop and innovate them.

Any Case Packer Manufacturer maintains their competitiveness by consistently developing and enhancing their goods. To take advantage of the newest automation trends and technology, they make research and development investments. They also put a lot of effort into developing long-lasting relationships with their customers by providing dependable and effective machinery along with top-notch customer support. Then, a Case Packer Supplier is able to sustain a competitive advantage in the worldwide market because of their reputation for quality and innovation.

Don't hesitate to choose Rothe Packtech for choosing the most superior Case Packer Manufacturer in Canada. See the impact that quality and innovation can have on your packaging processes. To find out more and increase the effectiveness of your packaging, visit Rothe Packtech right now!